Date:2019-08-14 Views:389 times

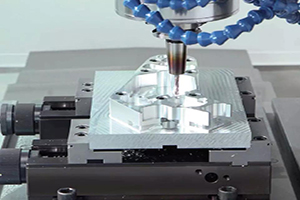

Before programming, it is necessary to analyze the process of the processed parts, draw up the processing plan, select the appropriate tool and determine the cutting parameters. In programming, some technological problems such as tool setting and machining route need to be dealt with. Therefore, the process analysis in programming is very important. When processing parts on ordinary machine tools, the operation procedure of each process is specified by the process specification or process card, and the operator processes the parts according to the steps specified in the process card. When machining parts on CNC machine tools, it is necessary to program all the technological process, technological parameters and displacement data to control the machining of machine tools.

Before programming, it is necessary to analyze the process of the processed parts, draw up the processing plan, select the appropriate tool and determine the cutting parameters. In programming, some technological problems such as tool setting and machining route need to be dealt with. Therefore, the process analysis in programming is very important. When processing parts on ordinary machine tools, the operation procedure of each process is specified by the process specification or process card, and the operator processes the parts according to the steps specified in the process card. When machining parts on CNC machine tools, it is necessary to program all the technological process, technological parameters and displacement data to control the machining of machine tools. The processing technology of NC machine tool is basically the same as that of ordinary machine tool in principle, but the whole process of NC machining is automatic, so it has its own characteristics

1. The content of working procedure is complex

This is because CNC machine tools are more expensive than ordinary machine tools. It is not cost-effective to only process simple processes, so more complex processes are usually arranged on CNC machine tools, and even processes that are difficult to complete on ordinary machine tools.

2. The arrangement of working steps is more detailed

This is because the problems that need not be considered in the processing technology of ordinary machine tools, such as the arrangement of working steps in the process, the determination of tool setting point, tool changing point and processing route, can not be ignored when compiling the processing technology of CNC machine tools.

3. Rely on the program to complete all the process.

4. NC machining program is the directive document of NC machine tool.

5. CNC machine tools are controlled by program instructions, and the whole process of machining is automatically carried out according to program instructions.

6. NC machining program not only includes the process of parts, but also includes the necessary process parameters to complete the process, such as cutting parameters, feed route, tool size number and machine tool movement process.

7. CNC machining has high efficiency, high machining accuracy, low labor intensity and strong adaptability to different workpieces.

GCI Testing Instrument Co., Ltd

Tel:+86 0769-22322732 Mobile:13794832878(wechat)

ATTN:Mr.chen Email:Janray@163.com

Address:No. 41, East Zone 2, Xinxing Street, Datangtou, Dongcheng District, Dongguan City

Copyright © GCI All Rights Reserved.

Pay attention to wechat

Browse mobile site